Switch Type Electric Actuator

1.Smaller and more precise, conducive to installation

2.More precise control and application

3.Basically no harsh noise during operation

4.More energy saving and environmental protection

5.Reduce the cost of the automated production industry

Switch Type Electric Actuator Gallery

Switch Type Electric Actuator

Switch Type Electric Actuator

Every LORZEN Switch Type Electric Actuator has gone through highly controlled conditions to ensure the high quality of your Electric Actuators.

Description

Electric actuators deliver precise valve control and automation through closed-loop PID algorithms, stepper/servo motors, and integrated sensors. Advanced features include programmable control, condition monitoring, and industrial communication.

Standard technical parameters

|

Function: |

On/off or modulating |

|

Housing: |

Aluminum alloy,epoxy powder coated |

|

Gear: |

Steel/aluminum bronze |

|

Screws: |

Stainless steel |

|

Indicator Cover: |

Polycarbonated |

|

Shaft/Adaptor: |

Alloy steel |

|

Seal: |

NBR |

|

Lubrication: |

Aluminum based grease |

|

Power Supply: |

24VDC,110VAC,220VAC |

|

Motor: |

Squirrel cage asynchronous motor |

|

Limit Switch |

SPDT,250VAC 10A,each for open and close positions |

|

Rotation: |

90° (±10°)other rotation on request |

|

Manual Operation: |

Mechanical handle standard |

|

Conduit Entry: |

2 x M18 |

|

Operating Temp: |

-20°C to + 70°C |

|

Ambient Humidity: |

Max.90%RH |

|

Vibration Tested: |

XYZ10g,0.2~34Hz,30 minutes |

|

Mounting: |

ISO5211 |

|

Torque Output: |

30Nm to 1000Nm (2000Nm on request) |

|

Self-locking device: |

Self-locking by worm and worm gear |

Performance Testing

Our state-of-the-art facilities allow rigorous testing to validate function, endurance and environmental protection.

Quality Assurance

100% testing and inspection ensures superior performance of every actuator.

LORZEN Electric Actuators Are Utilized Across Various Sectors, Including:

Actuator Design

Switch Type Electric Actuator Application

Electric actuators are used to control valves and other similar products that rotate from 0° to 270°, such as butterfly valves, ball valves, dampers, flapper valves, plug valves, shutter valves, etc., and can be widely used in petroleum, chemical, water treatment, shipbuilding, papermaking , power station, heating, building automation, light industry and other industries.

- +8613736966003

- sales@lorzval.com

- Lorzen Factory Park, Linyang Industrial District, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

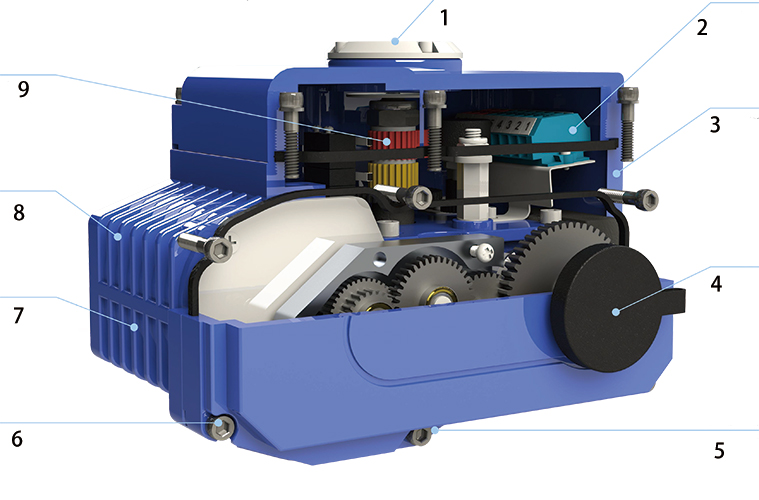

Switch Type Electric Actuator Product structure

Modulating Electric Actuators Product Features

Product introduction

Electric actuators are used to control valves and other similar products that rotate from 0° to 270°, such as butterfly valves, ball valves, dampers, flapper valves, plug valves, shutter valves, etc., and can be widely used in petroleum, chemical, water treatment, shipbuilding, papermaking , power station, heating, building automation, light industry and other industries. It uses 380V/220V/110V AC power as the driving power, and 4-20mA current signal or 0-10V DC voltage signal as the control signal, which can make the valve move to the desired position and realize its Double-linked cams are used to facilitat automatic control. The maximum output torque reaches 4000NM.

Product features

1.Location indication

The opening degree of the valve is displayed by plane pointer and scale, which takes up little space.

2.Terminal block

There are enough terminals to make it easy for the user to use and to ensure a tight, secure wire connection.

3.Terminal block

The long-term sealing ring design is adopted to effectively ensure the waterproof level.

4.Manual device

After the power is off, open the rubber protective cover and insert the matching Z-type wrench to manually open and close the valve

5.Connection flange

The bottom connection hole of the electric actuator is in accordance with the ISO5211 standard. There are two different sizes of double flanges and octagonal drive sleeves. The installation angle can be changed flexibly to achieve the purpose of flange connection with valves with different hole positions and angles.

6.Weather resistance

The shell is coated with anti-corrosion epoxy resin powder, which has strong adhesion and corrosion resistance. All fasteners are stainless steel for outdoor applications.

7.Safe operation

Class F insulated motor, the motor winding is equipped with a temperature control switch to sense the temperature of the motor, which can provide over-temperature protection and ensure the safe operation of the motor.

8.Appearance design

Patented streamlined appearance design, small size, light weight, suitable for applications in narrow spaces.

9.Limit function

Double-linked cams are used to facilitate the setting of stroke positions.