Single Acting Pneumatic Actuator

1.incorporate advanced precision machining equipment

2.highquality materials and industrial artistic design techniques.

3.rigorous testing and production line optimization

4.smooth and reliable operation

5.long service life,

6.wide adjustable range,

7.high corrosion resistance,

8.flexible selection,

9.cost-effectiveness.

Single Acting Pneumatic Actuator Gallery

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Single Acting Pneumatic Actuator

Every LORZEN Single Acting Pneumatic Actuator has gone through highly controlled conditions to ensure the high quality of your Pneumatic Actuators.

Description

Single acting pneumatic actuators utilize air pressure to provide a unidirectional stroke for operating quarter-turn valves. With a compact and lightweight design, they are an economical solution optimized for on-off applications across various industries. The spring-return mechanism allows reliable valve control in case of air supply failure.

Available in aluminum and stainless steel bodies with NPT threaded air connections, these actuators offer durability in most environments. Their adjustable cam allows easy modification of stroke length to suit different valves.

Our single acting actuators feature a 360° visual position indicator and adjustable travel stops for precise valve control. Please contact us to select the optimal size and configuration to suit your specification requirements.

Key Features

- Working Type: Rotary

- Pressure: Low Pressure

- Work Temperature: Normal Temperature

- Acting Type: Single Acting

- Material: Aluminum

- Structure: Piston Type

- Connection Form: Octagonal Square Center

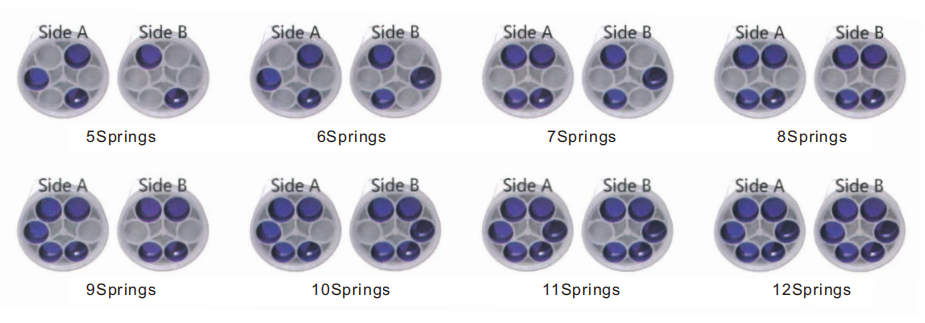

Spring Configuration

Installation form of single-acting actuator

In the matching process of single-acting actuators, if it is possible to understand the opening, running and closing of the valve. When the torque distribution is closed, we can choose the actuator more economically and reasonably.

Travel Time

Air source pressure:5bar ;Unit: seconds

| Single acting(number of springs) | ||||||||||||||

| 3+3 | 3+4 | 4+4 | 4+5 | 5+5 | 5+6 | 6+6 | ||||||||

| Size | 0°~90° | 90°~0° | 0°~90° | 90°~0° | 0°~90° | 90°~0° | 0°~90° | 90°~0° | 0°~90° | 90°~0° | 0°~90° | 90°~0° | 0°~90° | 90°~0° |

| 32SR | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 40SR | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 52SR | 2.46 | 0.48 | 2.48 | 0.46 | 2.5 | 0.44 | 2.52 0.42 | 0.42 | 2.54 | 0.4 | 2.56 | 0.38 | 2.58 | 0.36 |

| 63SR | 2.54 | 0.56 | 2.56 | 0.54 | 2.58 | 0.52 | 2.6 | 0.5 | 2.62 | 0.48 | 2.64 | 0.46 | 2.66 | 0.44 |

| 75SR | 2.62 | 0.64 | 2.64 | 0.62 | 2.66 | 0.6 | 2.68 | 0.58 | 2.7 | 0.56 | 2.72 | 0.54 | 2.74 | 0.52 |

| 83SR | 2.71 | 0.73 | 2.73 | 0.71 | 2.75 | 0.69 | 2.77 | 0.67 | 2.79 | 0.65 | 2.81 | 0.63 | 2.83 | 0.61 |

| 92SR | 2.89 | 0.86 | 2.91 | 0.84 | 2.93 | 0.82 | 2.95 | 0.8 | 2.97 | 0.78 | 2.99 | 0.76 | 3.01 | 0.74 |

| 105SR | 3.14 | 0.91 | 3.16 | 0.89 | 3.18 | 0.87 | 3.2 | 0.85 | 3.22 | 0.83 | 3.24 | 0.81 | 3.26 | 0.79 |

| 115SR | 3.59 | 1.02 | 3.61 | 1 | 3.62 | 0.98 | 3.64 | 0.96 | 3.66 | 0.95 | 3.67 | 0.93 | 3.69 | 0.91 |

| 125SR | 4.24 | 1.2 | 4.26 | 1.18 | 4.28 | 1.16 | 4.3 | 1.14 | 4.32 | 1.12 | 4.34 | 1.1 | 4.36 | 1.08 |

| 140SR | 4.4 | 1.35 | 4.4 | 1.33 | 4.62 | 1.31 | 4.64 | 1.29 | 4.66 | 1.27 | 4.68 | 1.25 | 4.68 | 1.22 |

| 160SR | 4.74 | 1.77 | 4.76 | 1.75 | 4.78 | 1.73 | 4.8 | 1.71 | 4.82 | 1.69 | 4.82 | 1.67 | 4.84 | 1.65 |

| 190SR | 5.75 | 3.7 | 5.77 | 3.5 | 5.75 | 3.48 | 5.77 | 3.46 | 5.79 | 3.44 | 5.8 | 3.42 | 5.83 | 3.4 |

| 210SR | 8.25 | 4.8 | 8.4 | 4.6 | 8.42 | 4.58 | 8.44 | 4.56 | 8.46 | 4.54 | 8.48 | 4.52 | 8.5 | 4.5 |

| 240SR | 16.2 | 5.14 | 16.4 | 5.12 | 16.42 | 5.1 | 16.44 | 4.9 | 16.6 | 4.98 | 16.8 | 4.86 | 17 | 4.84 |

| 270SR | 17.6 | 6.28 | 17.8 | 6.26 | 17.6 | 6.24 | 17.8 | 6.2 | 18 | 6.18 | 18.2 | 6.16 | 18.4 | 6.14 |

| 300SR | 24 | 13.2 | 24.5 | 13 | 24.4 | 12.8 | 24.3 | 12.6 | 24.5 | 12.58 | 24.7 | 12.56 | 24.9 | 12.54 |

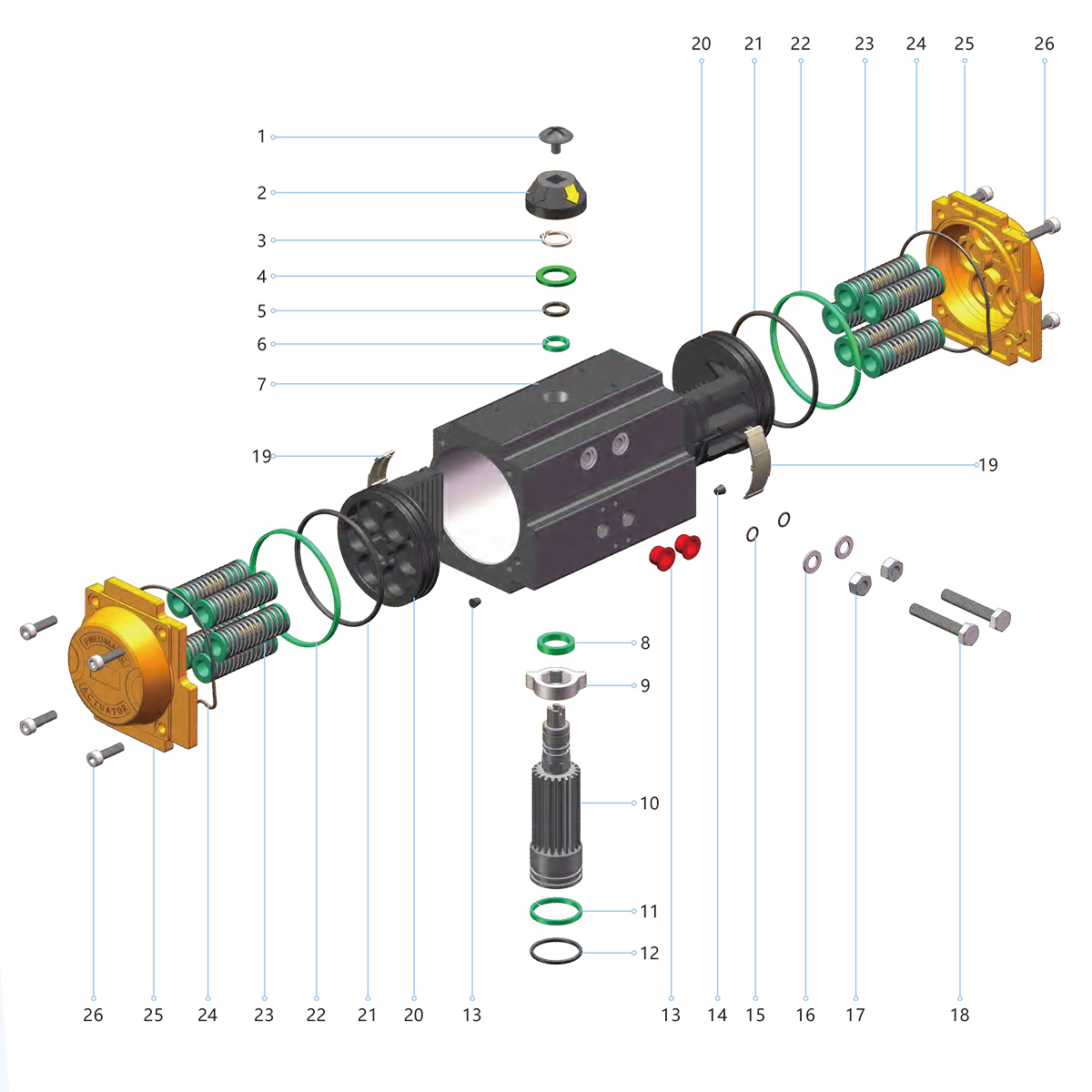

Parts and materials

| Serial number | Name | Quantity | Material | Anti-corrosion treatment | Optional material |

| 1 | Indicator screw | 11 | Engineering plastic+stainless steel | ||

| 2 | Indicator | 1 | Engineering plastics | ||

| 3 | Card reed | 1 | Stainless steel (304) | ||

| 4 | Outer gasket | 1 | Engineering plastics | ||

| 5 | Cylinder body | 1 | Aluminum profile (6005-T5) | ||

| 6 | Inner gasket | 1 | Engineering plastics | Hard oxidation,etc. | |

| 7 | Cam | 1 | 45 #steel | ||

| 8 | Upper shaft O pottery | 1 | NBR | ||

| 9 | Upper shaft support ring | 1 | Engineering plastics | Viton /HNBR | |

| 10 | Drive shaft | 1 | Alloy steel | ||

| 11 | Lower shaft support ring | 1 | Engineering piastics | Nickel phosphorus | Stainless steel (304) |

| 12 | Lower shaft O-ring | 1 | Plastic material | ||

| 13 | Defend dust plug | 1 | NBR | Viton/HNBR | |

| 14 | Plug | 1 | NBR | Viton/HNBR | |

| 15 | Adjusting bolt O-ring | 1 | Stainless steel (304) | ||

| 16 | Pad piece | 1 | Stainless steel (304) | ||

| 17 | Nut | 1 | Stainless steel (304) | ||

| 18 | Adjusting bolt | 1 | NBR | Oxygenchange | |

| 19 | Piston guide | 2 | Engineering plastics | ||

| 20 | Piston | 2 | Cast aluminum | Viton/HNBR | |

| 21 | Piston O-ring | 2 | NBR | ||

| 22 | Piston bearing ring | 2 | Engineering plastics | Electricity simming paint | |

| 23 | Spring | 0-12 | Spring steel | Viton/HNBR | |

| 24 | Build O-ring | 2 | NBR | Powder coating etc | |

| 25 | End cap | 2 | Cast aluminum | ||

| 26 | End cap screws | 2 | Stainless steel (304) |

Performance Testing

Our state-of-the-art facilities allow rigorous testing to validate function, endurance and environmental protection.

Quality Assurance

100% testing and inspection ensures superior performance of every actuator.

FAQ

1.Who are we?

We are real factory in Zhejiang, China, specialize in producing pneumatic actuator and electric actuator, sell to Mid East(40.00%), Southeast Asia(30.00%), South America(20.00%), Africa(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Pneumatic actuator, electric actuator, pneumatic valve, electric valve

4.Why should you buy from us not from other suppliers?

Introduce advanced technology and technology from the United States, have its own independent research and development team, and independently develop and produce high-quality new products in the field of fluid control

5.What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW

Accepted Payment Currency: USD, EURO, RMB

Accepted Payment Type: T/T, L/C, D/P, D/A, Credit Card, Western Union, Cash

Language Spoken: English, Chinese, Portuguese, French, etc

LORZEN Pneumatic Actuators Are Utilized Across Various Sectors, Including:

Actuator Design

Single Acting Pneumatic Actuator Selection

Under normal operating conditions. a safety factor of 20% - 30% is considered for double acting actuators

Example:

Valve torque= 100Nm

Safety torque- 100(1+ 30%) = 130Nm

Air source pressure=5Bar

Compared with the double-acting torque table, the specification of the optional Double-acting actuator is DA105.

- +8613736966003

- sales@lorzval.com

- Lorzen Factory Park, Linyang Industrial District, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

Single Acting Pneumatic Actuator Working Principle

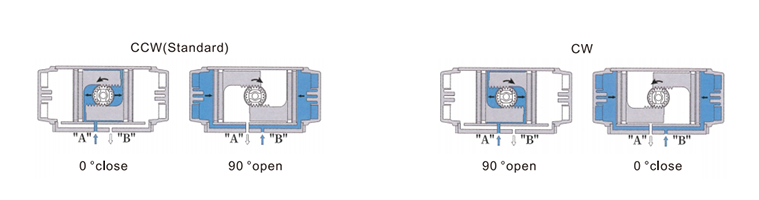

Double acting actuator

CCW(Standard)

lnlet A, compressed air pushes the piston outward,causing the actuator output shaft to rotatecounterclockwise (0 →90 ) and the B port is vented.lnlet at port B,compressed air pushes the piston Moveinward to rotate the output shaft of the actuatorclockwise (9o °→0 °), A port row.

CW

lnlet A,compressed air pushes the piston outward,causing the actuator output shaft to rotates clockwise(9o °→o ) and the B port is vented. Inlet at port B,compressed air pushes the piston Move inward torotate the output shaft of the actuator rotatescounterclockwise (0 °→90 °), A port row.

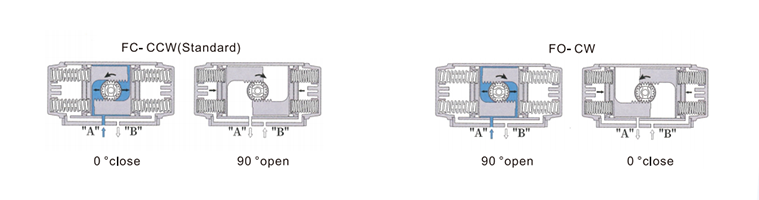

Single acting actuator

FC-CCW(Standard)

lnlet A, compressed air overcomes spring force,pushes the piston outward,and the actuator Outputshaft rotates counterclockwise (o。 → 90 ),B portexhausts: actuator loses air, piston Under the action ofthe spring force, it moves inward and the actuatoroutput shaft rotates clockwise (90 °→0 °), exhaustat port A.

FO-CW

lnlet air from port A, compressed air overcomes springforce and pushes the piston outward.The output shaftof the actuator rotates clockwise (90 ° o °), and port Bexhausts; The actuator loses air, and the piston movesinward under the action of spring force. The outputshaft of the actuator rotates counterclockwise (o ° 90), exhaust at port A.