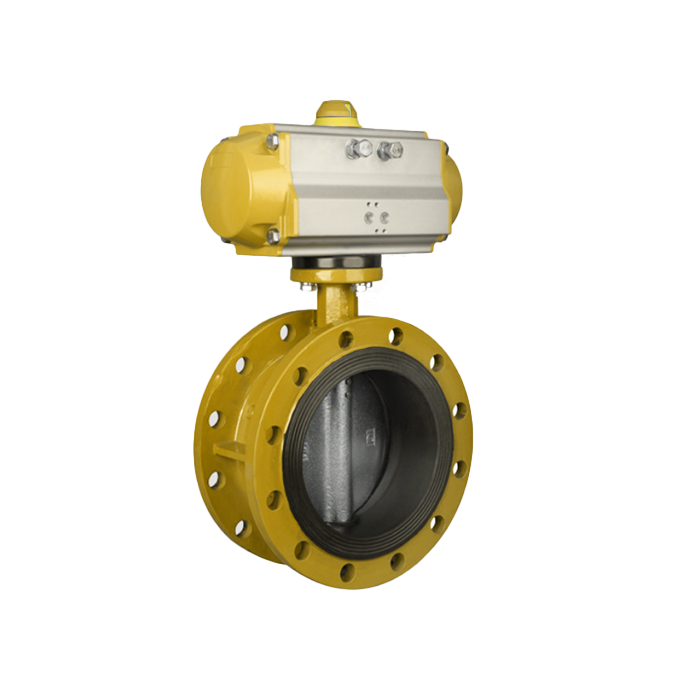

Pneumatic Actuated Butterfly Valve

1.Compact: Lightweight, easy to install.

2.Economical: Low initial and upkeep costs.

3.High Flow: Handles high flow rates.

4.Quick: Quarter-turn operation.

5.Versatile: Handles various applications.

6.Low Maintenance: Minimal upkeep needs.

7.Automatable: Allows for remote control.

8.Eco-friendly: Uses compressed air, energy-efficient.

Pneumatic Actuated Butterfly Valve Gallery

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Butterfly Valve

Every LORZEN Pneumatic Actuated Butterfly Valve has gone through highly controlled conditions to ensure the high quality of your Pneumatic Actuated Valves.

Product Features:

A Pneumatic Actuated Butterfly Valve is a type of flow control device that uses a disc mounted on a rotating shaft. When the valve is fully open, the disc is rotated a quarter turn to allow full passage of the fluid. When the valve is closed, the disc is rotated a quarter turn to block off the passage. The rotation of the disc is driven by a pneumatic actuator, which uses air pressure to create motion.

Compact Design: Butterfly valves are known for their compact and lightweight design, making them easy to install, especially in tight spaces.

Cost-Effective: Compared to other types of valves, butterfly valves are generally more cost-effective, both in terms of initial cost and maintenance.

High Capacity: Despite their small size, these valves can handle high flow rates effectively.

Quick Operation: The quarter-turn operation allows for quick opening and closing of the valve, which is beneficial in emergency situations.

Versatility: They can be used in a wide variety of applications, handling everything from water and air to corrosive chemicals, depending on the materials used.

Low Maintenance: Due to their simple design, they require less maintenance compared to other valve types.

Automation Capabilities: Like the ball valve, these valves can also be automated for remote control and monitoring, enhancing operational efficiency.

Environmentally Friendly: The use of compressed air as the actuating medium makes these valves an energy-efficient and environmentally friendly option.

A pneumatic actuated butterfly valve is a type of flow control device that regulates the flow of a fluid. The valve is controlled by a pneumatic actuator, which uses pressurized air to open or close the valve. The valve itself consists of a disc mounted on a rotating shaft. When the valve is closed, the disc is turned so that it completely blocks off the path. When the valve is open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid.

Key Features and Characteristics

Compact Design: Pneumatic actuated butterfly valves are known for their compact and lightweight design, making them easy to install and handle.

Cost-Effective: These valves are generally more economical than other types of valves. They have lower initial costs and require less maintenance, which results in lower overall operating costs.

High Flow Capacity: Despite their small size, these valves can handle high flow rates, making them suitable for large-scale applications.

Quick Operation: The pneumatic actuator allows for quick and efficient opening and closing of the valve, which is particularly useful in situations where rapid flow control is necessary.

Versatility: Pneumatic actuated butterfly valves are versatile and can be used in a wide range of applications, including water and wastewater treatment, HVAC, power generation, and process industries.

Low Maintenance: These valves have few moving parts and are therefore less likely to break down, resulting in lower maintenance requirements.

Automatable: The use of a pneumatic actuator allows for easy automation, enabling remote control and monitoring of the valve.

Eco-friendly: Pneumatic actuated butterfly valves use air pressure for operation, making them an energy-efficient and environmentally friendly option.

Standard technical parameters

| Type of Butterlfy Valve | Center line,double offset,triple offset |

| End connection | Flanged,Wafer,Lug |

| Size | 2”-78” ,DN40-DN2000 |

| Pressure | 150LB-900LB/PN16-PN400 |

| Application temperature | -40°~600° |

| Design | API609,DIN2559,JB/8527 |

| Body Material | Carbon steel,Cast iron,stainless steel,Cr.Mo. steel,Alloy steel etc. |

| Media | Water,Steam,petroleum,Liquefied Gas,Natural Gas,Oil etc. |

Performance Testing

Our state-of-the-art facilities allow rigorous testing to validate function, endurance and environmental protection.

Quality Assurance

100% testing and inspection ensures superior performance of every actuator.

LORZEN Pneumatic Actuated Valves Are Utilized Across Various Sectors, Including:

Actuator Design

Pneumatic Actuated Butterfly Valve Search

Under normal operating conditions. a safety factor of 20% - 30% is considered for double acting actuators

Example:

Valve torque= 100Nm

Safety torque- 100(1+ 30%) = 130Nm

Air source pressure=5Bar

Compared with the double-acting torque table, the specification of the optional Double-acting actuator is DA105.

- +8613736966003

- sales@lorzval.com

- Lorzen Factory Park, Linyang Industrial District, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

Pneumatic Actuated Butterfly Valve Related Information

Installation and Maintenance

Installation and Maintenance

The installation and maintenance of a Pneumatic Actuated Butterfly Valve are relatively straightforward. Here are some basic steps:

Installation: During the installation process, it’s important to ensure the actuator is correctly aligned and secured in the right position. The actuator should be properly interfaced with the driven device (such as a valve or other mechanical component) to ensure accurate and efficient operation.

Maintenance: Maintenance of the actuator typically involves regular inspections and replacement of worn parts. This might include replacing seals, cleaning and lubricating moving parts, and checking and adjusting the control system. In most cases, just carrying out these maintenance steps periodically can ensure long-term reliable operation of the actuator.

Industry Applications/Functional Uses

Industry Applications/Functional Uses

Pneumatic Actuated Butterfly Valves have a wide range of uses in many different industries and applications. Here are some of the main application areas:

Manufacturing: On automated production lines, these actuators can be used to control a variety of mechanical equipment such as valves, drums, conveyors, etc.

Energy Sector: In the oil, gas, and electricity industries, these actuators can be used to control various types of valves, ensuring efficient distribution and use of energy.

Chemical Industry: In chemical processes, these actuators can be used to precisely control conditions for various chemical reactions, such as temperature, pressure, and flow rate.

Water Treatment: In water treatment facilities, these actuators can be used to control various equipment like pumps, valves, and filters, ensuring effective water treatment.

Food and Beverage Industry: In the production process of food and beverages, these actuators can be used to control various equipment like mixers, ovens, and packaging machines, ensuring efficiency and quality in the production process.

These are just some of the main application areas for Pneumatic Actuated Butterfly Valve. Thanks to their simple design and operating principle, these actuators can adapt to a variety of different applications and environments.