Double Acting Pneumatic Actuator

1.incorporate advanced precision machining equipment

2.highquality materials and industrial artistic design techniques.

3.rigorous testing and production line optimization

4.smooth and reliable operation

5.long service life,

6.wide adjustable range,

7.high corrosion resistance,

8.flexible selection,

9.cost-effectiveness.

Double Acting Pneumatic Actuator Gallery

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Double Acting Pneumatic Actuator

Every LORZEN Double Acting Angular Stroke Pneumatic Actuator has gone through highly controlled conditions to ensure the high quality of your Pneumatic Actuators.

Product Description

Our double acting pneumatic actuators use air pressure to provide bidirectional stroke for reliable valve control. The piston design allows both extend and retract movements to open and close process valves.

Available in aluminum, stainless steel, these actuators are built for durability in most industrial environments. With multiple mounting options and accessories, they integrate seamlessly with various valve types and piping setups.

The adjustable travel stops allow easy stroke adjustment according to your specifications. Our double acting actuators feature high flow rates and fast response times for efficient valve actuation.

Contact our engineering team to select the optimal size, materials and configuration based on your operating parameters and design requirements.

Key Features

- Working Type: Rotary

- Pressure: Low Pressure

- Work Temperature: Normal Temperature

- Acting Type: Double Acting

- Material: Aluminum

- Structure: Piston Type

- Connection Form: Octagonal Square Center

| Model | Air pressure | ||||||||||

| 2Bar | 2.5Bar | 3Bar | 3.5Bar | 4Bar | 4.5Bar | 5Bar | 5.5Bar | 6Bar | 7Bar | 8Bar | |

| DA-32 | 3 | 4 | 5 | 6 | 6 | 7 | 8 | 8 | 9 | 11 | 12 |

| DA-40 | 5 | 6 | 7 | 8 | 10 | 11 | 12 | 13 | 14 | 17 | 19 |

| DA-52 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 2P | 24 | 28 | 32 |

| DA-63 | 15 | 18 | 22 | 25 | 29 | 33 | 36 | 40 | 44 | 51 | 58 |

| DA-75 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 70 | 80 |

| DA-83 | 31 | 39 | 47 | 55 | 63 | 70 | 78 | 86 | 94 | 110 | 125 |

| DA-92 | 45 | 56 | 68 | 79 | 90 | 102 | 113 | 124 | 135 | 158 | 181 |

| DA-105 | 66 | 83 | 99 | 116 | 132 | 149 | 165 | 182 | 198 | 231 | 264 |

| DA-115 | 86 | 108 | 130 | 151 | 173 | 194 | 216 | 238 | 259 | 302 | 346 |

| DA-125 | 100 | 125 | 150 | 176 | 200 | 226 | 251 | 276 | 301 | 351 | 401 |

| DA-140 | 171 | 214 | 256 | 299 | 342 | 385 | 427 | 470 | 513 | 598 | 684 |

| DA-160 | 266 | 332 | 399 | 466 | 532 | 598 | 665 | 731 | 798 | 931 | 1064 |

| DA-190 | 426 | 532 | 638 | 745 | 851 | 958 | 1064 | 1170 | 1277 | 1490 | 1702 |

| DA-210 | 532 | 665 | 798 | 931 | 1064 | 1197 | 1330 | 1463 | 1596 | 1862 | 2128 |

| DA-240 | 769 | 962 | 1154 | 1347 | 1539 | 1731 | 1924 | 2116 | 2308 | 2693 | 3078 |

| DA-270 | 1170 | 1462 | 1754 | 2047 | 2339 | 2632 | 2924 | 3216 | 3509 | 4094 | 4679 |

| DA-300 | 1526 | 1908 | 2289 | 2671 | 3052 | 3434 | 3815 | 4197 | 4578 | 5341 | 6104 |

Performance Testing

Our state-of-the-art facilities allow rigorous testing to validate function, endurance and environmental protection.

Quality Assurance

100% testing and inspection ensures superior performance of every actuator.

1.Who are we?

We are real factory in Zhejiang, China, specialize in producing pneumatic actuator and electric actuator, sell to Mid East(40.00%), Southeast Asia(30.00%), South America(20.00%), Africa(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Pneumatic actuator, electric actuator, pneumatic valve, electric valve

4.Why should you buy from us not from other suppliers?

Introduce advanced technology and technology from the United States, have its own independent research and development team, and independently develop and produce high-quality new products in the field of fluid control

5.What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW

Accepted Payment Currency: USD, EURO, RMB

Accepted Payment Type: T/T, L/C, D/P, D/A, Credit Card, Western Union, Cash

Language Spoken: English, Chinese, Portuguese, French, etc

LORZEN Pneumatic Actuators Are Utilized Across Various Sectors, Including:

Actuator Design

Double Acting Pneumatic Actuator Selection

Under normal operating conditions. a safety factor of 20% - 30% is considered for double acting actuators

Example:

Valve torque= 100Nm

Safety torque- 100(1+ 30%) = 130Nm

Air source pressure=5Bar

Compared with the double-acting torque table, the specification of the optional Double-acting actuator is DA105.

- +8613736966003

- sales@lorzval.com

- Lorzen Factory Park, Linyang Industrial District, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

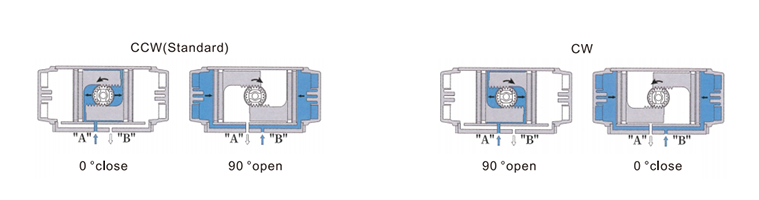

Double Acting Pneumatic Actuator Working Principle

Double acting actuator

CCW(Standard)

lnlet A, compressed air pushes the piston outward,causing the actuator output shaft to rotatecounterclockwise (0 →90 ) and the B port is vented.lnlet at port B,compressed air pushes the piston Moveinward to rotate the output shaft of the actuatorclockwise (9o °→0 °), A port row.

CW

lnlet A,compressed air pushes the piston outward,causing the actuator output shaft to rotates clockwise(9o °→o ) and the B port is vented. Inlet at port B,compressed air pushes the piston Move inward torotate the output shaft of the actuator rotatescounterclockwise (0 °→90 °), A port row.

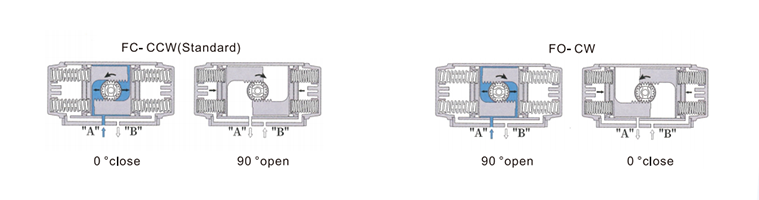

Single acting actuator

FC-CCW(Standard)

lnlet A, compressed air overcomes spring force,pushes the piston outward,and the actuator Outputshaft rotates counterclockwise (o。 → 90 ),B portexhausts: actuator loses air, piston Under the action ofthe spring force, it moves inward and the actuatoroutput shaft rotates clockwise (90 °→0 °), exhaustat port A.

FO-CW

lnlet air from port A, compressed air overcomes springforce and pushes the piston outward.The output shaftof the actuator rotates clockwise (90 ° o °), and port Bexhausts; The actuator loses air, and the piston movesinward under the action of spring force. The outputshaft of the actuator rotates counterclockwise (o ° 90), exhaust at port A.