Customized Pneumatic Actuator

1.Material Customization: The materials used in the construction of the actuator can be customized to withstand specific environmental conditions, such as high temperatures, corrosive substances, or extreme pressures.

2.Customized Control Systems: The control systems of the actuator can be customized, including the type of control valves used, control signals, and types of feedback mechanisms.

Customized Pneumatic Actuator Gallery

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Customized Pneumatic Actuator

Every LORZEN Customized Pneumatic Actuator has gone through highly controlled conditions to ensure the high quality of your Pneumatic Actuators.

Technical features

1.Specific Force, Speed, and Stroke Length: Customized pneumatic actuators can be designed to provide specific force, speed, or stroke length to meet the requirements of a particular application.

2.Material Customization: The materials used in the construction of the actuator can be customized to withstand specific environmental conditions, such as high temperatures, corrosive substances, or extreme pressures.

3.Customized Control Systems: The control systems of the actuator can be customized, including the type of control valves used, control signals, and types of feedback mechanisms.

4.Improved Performance: Customized pneumatic actuators can provide superior performance compared to standard actuators.

5.Higher Efficiency: By precisely matching application requirements, customized pneumatic actuators can improve system efficiency.

6.Enhanced Reliability: Customized pneumatic actuators can be designed to provide higher reliability in specific environments or applications.

7.Space Adaptability: Customized pneumatic actuators can be designed to fit spaces that standard actuators can’t, making them an ideal choice for space-constrained applications.

8.Compliance with Safety Standards and Regulatory Requirements: Customized pneumatic actuators can be designed to meet specific safety standards or regulatory requirements, ensuring compliance with industry regulations.

9.Wide Range of Applications: Whether for unique industrial processes, challenging operating environments, or specific control requirements, customized pneumatic actuators can provide the ideal solution.

Product Description

A Customized Pneumatic Actuator is a type of actuator that is specifically designed and tailored to meet the unique needs of a particular application or system. Pneumatic actuators use pressurized air to create mechanical motion, and they are commonly used in a variety of industries including oil and gas, water treatment, and manufacturing.

Customization of a pneumatic actuator can involve several aspects. It can be designed to deliver a specific force, speed, or stroke length, depending on the requirements of the application. The materials used to construct the actuator can also be customized to withstand specific environmental conditions, such as high temperatures, corrosive substances, or extreme pressures.

In addition, the control systems for the actuator can also be customized. This includes the type of control valve used (such as proportional, on/off, or servo valves), the control signals (like 4-20mA, 0-10V, or digital signals), and even the type of feedback mechanism used to provide information about the actuator’s position or status.

Customized pneumatic actuators can provide several benefits. They can deliver improved performance, greater efficiency, and enhanced reliability compared to standard actuators. They can also be designed to fit into spaces where standard actuators cannot, making them ideal for applications with space constraints. Furthermore, they can be designed to meet specific safety standards or regulatory requirements, ensuring compliance with industry regulations.

In conclusion, a Customized Pneumatic Actuator is a versatile and adaptable solution that can be tailored to meet the specific needs of a wide range of applications. Whether it’s for a unique industrial process, a challenging operating environment, or a specific control requirement, a customized pneumatic actuator can provide the ideal solution.

Key Features

- Key Features

- Working Type: Rotary

- Pressure: Low Pressure

- Work Temperature: Normal Temperature

- Acting Type: As per requirement

- Material: As per requirement

- Structure: Piston Type

- Connection Form: Octagonal Square Center

|

item

|

Pneumatic actuator

|

|

Condition

|

New

|

|

Warranty

|

1 YEAR

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Construction works , Energy & Mining

|

|

After Warranty Service

|

Video technical support, Online support

|

|

Local Service Location

|

None

|

|

Showroom Location

|

None

|

|

Place of Origin

|

China

|

|

Product name

|

Pneumatic actuator

|

|

Working medium

|

Compressed Air

|

|

Fluid

|

Air

|

|

Application

|

Pneumatic Component

|

|

Body Material

|

Aluminum Alloy

|

|

Color

|

Black

|

|

Material

|

Aluminum

|

|

Type

|

Actuator

|

|

Power

|

Pneumatic

|

|

MOQ

|

5 PCS

|

Performance Testing

Our state-of-the-art facilities allow rigorous testing to validate function, endurance and environmental protection.

Quality Assurance

100% testing and inspection ensures superior performance of every actuator.

1.Who are we?

We are real factory in Zhejiang, China, specialize in producing pneumatic actuator and electric actuator, sell to Mid East(40.00%), Southeast Asia(30.00%), South America(20.00%), Africa(10.00%). There are total about 51-100 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Pneumatic actuator, electric actuator, pneumatic valve, electric valve

4.Why should you buy from us not from other suppliers?

Introduce advanced technology and technology from the United States, have its own independent research and development team, and independently develop and produce high-quality new products in the field of fluid control

5.What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW

Accepted Payment Currency: USD, EURO, RMB

Accepted Payment Type: T/T, L/C, D/P, D/A, Credit Card, Western Union, Cash

Language Spoken: English, Chinese, Portuguese, French, etc

LORZEN Pneumatic Actuators Are Utilized Across Various Sectors, Including:

Actuator Design

Customized Pneumatic Actuator Selection

Under normal operating conditions. a safety factor of 20% - 30% is considered for double acting actuators

Example:

Valve torque= 100Nm

Safety torque- 100(1+ 30%) = 130Nm

Air source pressure=5Bar

Compared with the double-acting torque table, the specification of the optional Double-acting actuator is DA105.

- +8613736966003

- sales@lorzval.com

- Lorzen Factory Park, Linyang Industrial District, Oubei Town, Yongjia County, Wenzhou City, Zhejiang Province, China

Customized Pneumatic Actuator Working Principle

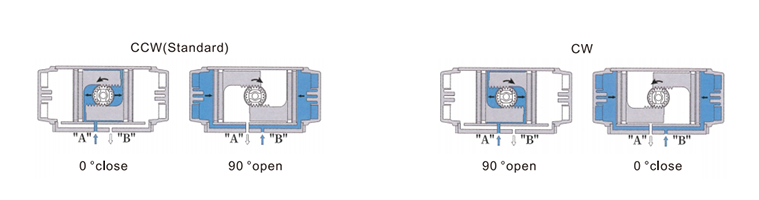

Double acting actuator

CCW(Standard)

lnlet A, compressed air pushes the piston outward,causing the actuator output shaft to rotatecounterclockwise (0 →90 ) and the B port is vented.lnlet at port B,compressed air pushes the piston Moveinward to rotate the output shaft of the actuatorclockwise (9o °→0 °), A port row.

CW

lnlet A,compressed air pushes the piston outward,causing the actuator output shaft to rotates clockwise(9o °→o ) and the B port is vented. Inlet at port B,compressed air pushes the piston Move inward torotate the output shaft of the actuator rotatescounterclockwise (0 °→90 °), A port row.

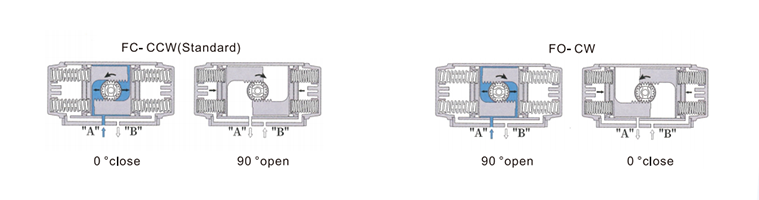

Single acting actuator

FC-CCW(Standard)

lnlet A, compressed air overcomes spring force,pushes the piston outward,and the actuator Outputshaft rotates counterclockwise (o。 → 90 ),B portexhausts: actuator loses air, piston Under the action ofthe spring force, it moves inward and the actuatoroutput shaft rotates clockwise (90 °→0 °), exhaustat port A.

FO-CW

lnlet air from port A, compressed air overcomes springforce and pushes the piston outward.The output shaftof the actuator rotates clockwise (90 ° o °), and port Bexhausts; The actuator loses air, and the piston movesinward under the action of spring force. The outputshaft of the actuator rotates counterclockwise (o ° 90), exhaust at port A.